Tianjin researchers develop low-cost propylene catalyst

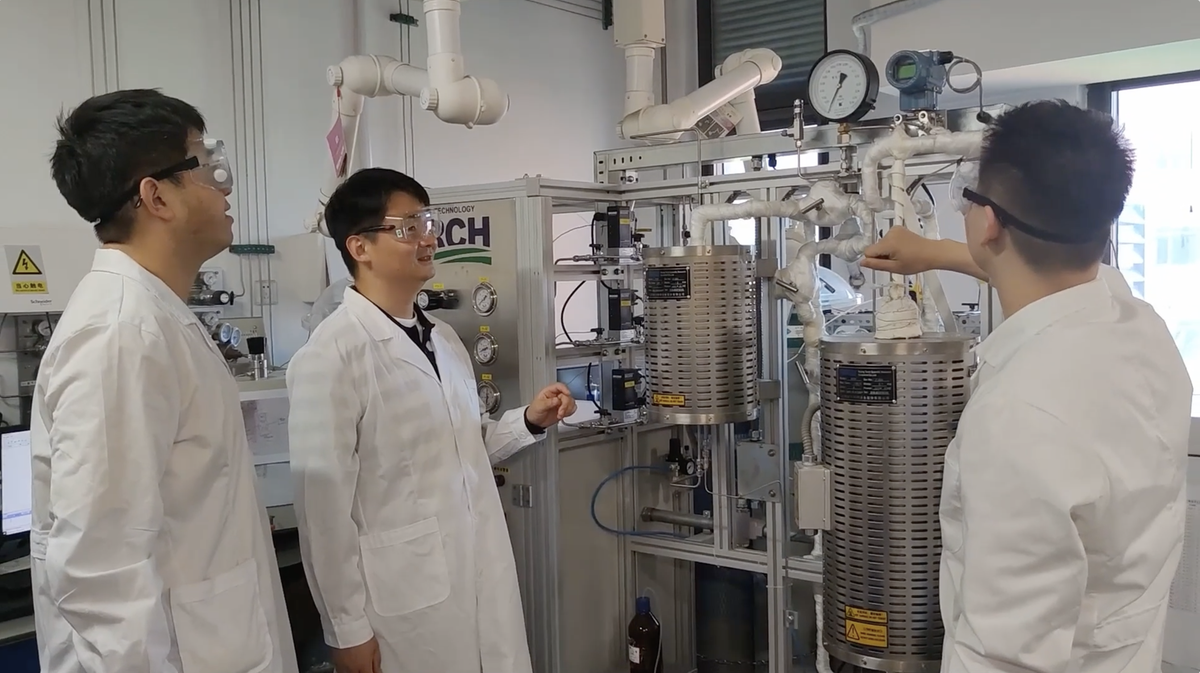

Researchers in Tianjin say they have developed a catalyst technology that could slash the cost of propylene production by up to 90 percent while sharply reducing carbon emissions. The breakthrough, which nearly eliminates waste in the use of expensive noble metals, could reshape one of the chemical industry's most essential processes.

Propylene is a building block for plastics, synthetic fibers, and rubber, making it indispensable to industries from healthcare and textiles to agriculture and defense. Producing it at scale requires catalysts, many of which rely on rare metals such as platinum and palladium. These metals are costly to mine, limited in supply, and often used inefficiently: inside conventional catalysts, many atoms clump together or stay buried, unable to contribute to the reaction.

"In 2024, the global usage of precious metals in catalysts reached nearly 200 billion yuan ($28 billion)," said Gong Jinlong, a member of the research team and president of Tianjin Normal University. Despite the value, developing more efficient and cost-effective alternatives remains a global challenge.

After more than a decade of research, Gong's team at Tianjin University developed a method they call "atomic extraction". The technique introduces tin atoms to the surface of a platinum–copper alloy. The tin acts like a magnet, pulling platinum atoms from deep inside the catalyst to the surface where they can participate in the reaction.

This approach puts nearly every platinum atom to work, rather than just a fraction, according to Fu Donglong, a member of the research team and a faculty member at the School of Chemical Engineering at Tianjin University. "This reduces production costs and improves propylene generation efficiency."

In lab tests, the exposure ratio of platinum on the catalyst surface rose from about 30 percent to nearly 100 percent. That efficiency means the process requires only one-tenth the platinum of today's best-performing catalysts, while delivering superior output of propylene.

The result: a potential 90 percent cut in catalyst costs, plus lower dependence on scarce metals. Because the technology reduces carbon buildup on the catalyst surface, it also eliminates the need to burn away deposits during production — avoiding unnecessary carbon dioxide emissions.

Although the work is still at the laboratory stage, Gong estimates it may be ready for industrial application within five to ten years. Beyond propylene, the approach could inform the design of other precious-metal catalysts, extending to low-carbon chemical engineering and clean energy.

Wang Xiaojing contributed to this story.

- Tianjin researchers develop low-cost propylene catalyst

- Wuqiao International Circus Festival opens Sept 28 in Hebei

- Guangxi middle school student jumps from school building after stabbing classmate

- Village reaps benefits of millet harvest through collective effort

- Shanghai University leads global initiative

- NHSA releases new guidelines for long-term care insurance services